Today we will continue talking about casting and Casting Prep. I know some of you, maybe a lot of you do not do your own casting but bear with me…. I have always known that some of the stuff we talk about is not for everyone, but it IS for someone, Every Day. Today we will be “treeing up some waxes getting ready to cast them into Silver.

Start with your base. You will want to get a weight of your rubber base in grams or dwt, which ever you will be using to weigh your metal. I used grams in this instance and I write the weight on the Rubber Base. This is my “tare weight” which I will subtract from the total weight when I am done to find out how much wax I have, therefore how much silver to use. I am using a 4″ base here, but they make them in different sizes as well.

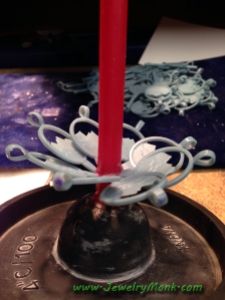

I now add a Wax Stem to the base, you can get these in different sizes and shapes. I use a straight one, but they make them tapered as well. Make sure you have a good seam between the base and the wax. We do not want any pits or holes here or it will cause trouble in the casting process by breaking off investment and getting it in the casted metal. I use a Paddle Wax Tip on my Wax Pen

which I have modified a bit to make it a little slimmer.

Now trim some of the excess sprue off of the wax you are treeing up with the wax tip. Make sure you wipe the tip off on a piece of paper towel or a napkin. If you don’t do this, the tip will have extra melted wax on it and this wax will drip onto your pieces or tree in places you do not want it, making a mess or destroying your waxes.

Next, start applying your waxes to your tree. In most cases you will probably only be casting a few pieces at a time, I have a bunch to do here. I try to get them as close as I can, while still leaving a little room between pieces. Make sure you leave room between your waxes and your metal can (I will show this later) minimum 1/4″ or so. Also do not get to close to the top of the can. (approx 1″)

There you have it, and that is why they call it a tree…..

Have an awesome day and go make something pretty!

Doug