This little “Bezel Pendant” project started a few days ago when I got the bright idea to show how to make a “V-Bezel” after I had the need for one. I thought I would show the process after I got a few comments and questions on application, so I said to myself, “well self, let’s just show how U would use one”. Today I will show how I finished the setting and finishing on this pendant.

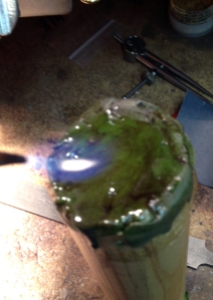

Just as I have used before, I mount the pendant in Dop Wax to secure it during setting. I have some dop wax pre-loaded on different sizes of wooden dowels. I “slightly” heat the surface of the wax, as well as the pendant with my Mini Torch

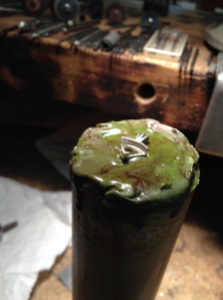

, not too hot or it will sink too deep into the wax. After the pendant is settled in the wax, I press or mold the inside of the wax to make room for the bottom of the stone.

After the piece has set into the wax and is cool enough to handle, I scribe a line with my Dividers, on both the large bezel and the “V” bezel. I mark the line from the base of the setting on both, so the seats I cut will be the same height and the stone will sit level.

Now I carefully cut a “seat” into the bezel. You will want to check out the stone’s girdle and match the shape of the girdle with the cut. In this instance, the Amethyst has a very thick girdle, so I cut the stone seat with a 2.5mm Hart Bur, following the scribed line as best as possible. After the initial cut is made, I shaped the bottom of the seat with a 1.2mm Ball Bur

to match the stone as best as I could.

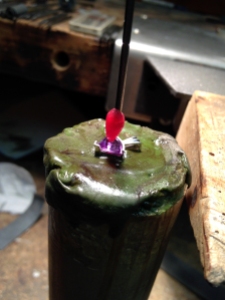

The V-Bezel is cut a bit differently. Since the stone end that is going to be secured is pointed and therefore more fragile, you will want to drill a small hole or divot (not all the way through) into the bezel where the point will be so there is no pressure on that point of the stone. The rest of the seat can be cut with a ball bur, once again trying to match the shape of the stone’s girdle. As you are cutting the seats, you will want to constantly check the stone against the seat, to see how well they match. I hold the stone with a small piece of sticky red wax on the end of an old bur or a nail.

After the seats are cut, place the stone in the setting and press the bezel over the stone carefully with a Flat End Prong Pusher. Slowly push the corners first to secure the stone, then “fold” the rest of the bezel over the stone. Be careful not to add too much pressure and constantly check the stone for tightness.

Now that the stone is set secure, remove the pendant from the Dop Wax by adding as little heat as possible until the wax releases the pendant. Place the pendant in Alcohol to dissolve the wax, in an Ultrasonic Cleaner

to speed up the process. Make sure the stone can tolerate the heat, alcohol, and ultrasonic waves beforehand. After the piece is cleaned from the wax, use rubber wheels and polishing wheels to finish the bezels. They look better the flatter you can get them. BE CAREFUL not to touch the stone with the wheels as you are finishing the bezels.

Finally finish polishing the pendant on a polishing wheel with Red Rouge. Clean with an Ultrasonic Cleaner and a Steam Cleaning Machine

.

There you have it, an extended lesson on how to make a V-Bezel and how to use it in an application. I hope you enjoyed it and it has opened up some ideas for you. Feel free to comment or share.

By the way, if there are things you would like to see on JewelryMonk, let me know.

Thanks for coming along this journey, now go make something brilliant!

Doug

Comments

22 responses to “Day 19 Setting a Bezel Stone”

Thank you!

Thank you!

My Pleasure Linda….. Really!

Thank you so much for your generosity in sharing your wonderful knowledge..

Lesley

Your welcome Lesley.

Thank you for providing these tips. I know it takes a lot of time to write them up and take the photos, so I want to thank you for your time and effort as well as sharing your knowledge. I’m currently working on bezel setting a 5mm trillion cut faceted stone for part of an earring, so maybe a tip along the lines of bezel setting small non round stones.

Thanks. I plan on doing a whole series on different types setting in the future.

Thank you for providing these tips. I know it takes a lot of time to write them up and take the photos, so I want to thank you for your time and effort as well as sharing your knowledge. I’m currently working on bezel setting a 5mm trillion cut faceted stone for part of an earring, so maybe a tip along the lines of bezel setting small non round stones.

Thanks. I plan on doing a whole series on different types setting in the future.

Thanks Laura, I will add that to the future list.

Thanks Laura, I will add that to the future list.

One more thank you to add to the pile. Great pictures- they help a lot.

This is probably really basic. I’ve seen tutorials on how to make a tube setting but am unsure the best way to solder the tube to a base. Would this be something you could demonstrate.

Thanks, I can do that.

One more thank you to add to the pile. Great pictures- they help a lot.

This is probably really basic. I’ve seen tutorials on how to make a tube setting but am unsure the best way to solder the tube to a base. Would this be something you could demonstrate.

Thanks, I can do that.

I am hopeless at prong settings – more in this area would be appreciated. Thank you again for all your time to share your knowledge. And more close ups of the tools being used.

Thanks. I plan on doing a whole series on different types setting in the future.

I am hopeless at prong settings – more in this area would be appreciated. Thank you again for all your time to share your knowledge. And more close ups of the tools being used.

Thanks. I plan on doing a whole series on different types setting in the future.

Thanks for sharing your knowledge and bright ideas.

I don’t have dop vax bit black pitch – can you explain the difference, please?

Can black pitch also be used for stone cutting? (I have plans trying that later on … 😉 )

I am not really familiar with the black pitch, I know it is used in chasing and repousse’. Not sure if it is good for stone cutting or not.

Doug