Making tools again today. To get a nice flat surface or a clean edge, a sanding stick works really well. I have used wooden sanding sticks and plastic sanding sticks before, but truthfully, I like a good aluminum one because it just feels a little more substantial in my hand, it remains flat and true, doesn’t bend like a plastic one, and it doesn’t “grove” like wooden ones can. Today I will show you how to make your own aluminum sanding sticks that will last you forever.

All you will need is a trip to the hardware store, (or online) buy Aluminum Flat Bar that is 1/8″ x 3/4″ in a length that will be long enough to make as many sticks as you want. I have 2 of them for 2 different grits of sandpaper. The sticks are 12″ long (1 foot). You will also want to buy some sheets of Wetordry Sandpaper

. I use 400 Grit

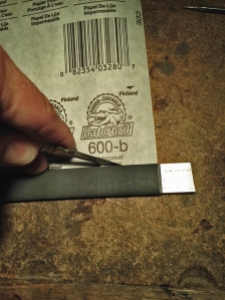

and 600 Grit

, but you can use the grit you want. I have used 320 grit and 1000 grit as well, but found out I didn’t use them very much. The 320 grit was similar to my #4 Flat Hand File

, and the 1000 was a bit too fine, and I found I could polish after the 600 grit sandpaper.

Place the sandpaper face down and place the aluminum stick along the edge and “score” or scratch a line along the edge, just hard enough to leave a mark in the paper but not all the way through the paper. After you score the line, bend the paper over to make the scored line nice and sharp. Fold over and continue. You could do this if you like your edges sharp, or you could just wrap the sandpaper around the aluminum stick. I make about 3 complete wraps, then trim off the excess with a Surgical Blade in a Scalpel Handle

.

After I trim the sandpaper, I wrap the end with Masking Tape to hold it in place and write the number of the sandpaper on the tape, so I can identify it quickly. (4 = 400, 6 = 600)

Again, the reason I like the aluminum is because it is light weight, inexpensive to make, long-lasting, won’t mark, grove or bend, and substantial feeling in my hand.

Thanks for stopping by today, I hope my tool “Geekiness” is not boring you.

Enjoy your day and go make something outrageously beautiful!

Doug

Comments

10 responses to “Day 24 Aluminum Sanding Sticks”

Thank God I have found you!!!!

Diane, thanks for the vote of confidence, that just confirms what I am doing. I have wanted to do this for a long time, just decided to get off my “duff” and do it.

Stay tuned, some exciting things are around the bend at JewelryMonk.com, like video lessons and 30 day specialized intensive online courses on metalsmithing, stone setting, etc, as well as a Podcast coming soon.

Thanks again!

Doug

I have a long strip of aluminum and didn’t know what to do with it! I’m so happy I found you too! Thank you for sharing such wonderful information with us. Please don’t ever stop! 🙂

Thanks Adele, glad I could help.

How wonderful that you are compelled to share all this great knowledge with us. I for one learn something new everyday. Thank you for your generosity.

You are welcome Debbie. I have all these “nuggets” of info and they are nothing if not shared.

[…] Notice how I have shaped my bench pin, on one side, there is a notch on top to place pieces against it to help support while I file. I flatten the side of the shank with a #2 Flat Hand File, then a #4 Flat Hand File. I finish the sides with using my Aluminum Sanding Sticks (400 grit and 600 grit) that I demonstrated in the Day 24 Blog post. […]

Newbie here. I’m gonna do one tip per day for 30 days. Today I learned to make sanding sticks. Thanks.

Welcome Nan. I like your enthusiasm.

[…] I clean up the solder on the inside with a #4 Crossing Needle File, and on the outside with a #4 Barrette Needle File. I use a #4 Flat Hand File on the sides of the shank, and finish it off with my #4 and #6 Sanding Stick (see Day 24) […]